Additive Manufacturing (AM)

Additive Manufacturing (AM), commonly known as 3D printing, is a transformative manufacturing process that builds three-dimensional objects layer by layer from digital models, typically using CAD files. Unlike subtractive methods (e.g., CNC machining or EDM), AM adds material only where needed, enabling complex geometries, reduced waste, and rapid prototyping. It is widely used in aerospace, defense, medical, and industrial applications, particularly for small to medium-sized parts with intricate designs or exotic materials.

Key Features

Process:

Material is deposited, fused, or cured in layers (0.01–0.3 mm thick) using techniques like laser melting, electron beam melting, or binder jetting.

Common methods include:

Fused Deposition Modeling (FDM): Extrudes thermoplastic filament (e.g., ABS, PEEK) for prototyping.

Selective Laser Sintering (SLS)/Melting (SLM): Fuses metal or polymer powders with lasers for high-strength parts.

Electron Beam Melting (EBM): Uses electron beams for metals like titanium in aerospace.

Stereolithography (SLA): Cures liquid resin with UV light for high-precision medical or electronic components.

Direct Energy Deposition (DED): Deposits and fuses metal for large weldments or repairs.

Materials:

Metals: Titanium, Inconel, aluminum, stainless steel, cobalt-chromium (aerospace, medical).

Polymers/Composites: PEEK, nylon, carbon-fiber-reinforced plastics (medical, aerospace).

Ceramics: Alumina, zirconia for high-temperature or biocompatible applications.

Tolerances: Typically, ±0.1 mm to ±0.01 mm, with post-processing (e.g., CNC machining) achieving tighter tolerances.

Applications

Aerospace/Defense:

Complex components like lightweight lattice structures, turbine blades, or waveguide parts.

Rapid prototyping of chassis or structural weldments, reducing lead times for AS9100-compliant parts.

Examples: GE Aviation’s LEAP engine fuel nozzles, lightweight drone frames.

Medical:

Custom implants (e.g., titanium hip joints, PEEK spinal cages) tailored to patient anatomy.

Surgical guides, dental prosthetics, or biocompatible scaffolds for tissue engineering.

Electronics: Miniature enclosures or connectors for RF systems, leveraging precise SLA or SLS.

Prototyping: Enables rapid iteration of small, intricate parts, complementing Swiss machining or EDM for finishing.

Integration with other manufacturing processes

Precision/Swiss Machining: AM creates near-net-shape parts that Swiss machining or EDM refines for ultra-tight tolerances (e.g., ±0.0001 inches), especially for medical implants or aerospace waveguides.

Weldments: DED AM can build or repair large weldments (e.g., turbine housings), reducing material waste compared to traditional fabrication.

Exotic Materials: AM excels with titanium, Inconel, or PEEK, aligning with aerospace and medical needs for high-strength, biocompatible components.

Surface Coatings: AM parts often receive plasma spray or HVOF coatings to enhance wear, corrosion, or thermal resistance, critical for aerospace chassis or medical implants.

Work Holding Fixtures: AM can produce custom fixtures, baseplates, or shims for unique geometries, supporting machining or welding of complex weldments.

EDM: AM parts with rough surfaces or loose tolerances may undergo Wire or Sinker EDM for precision finishing, especially for intricate aerospace or medical components.

Advantages

Complex Geometries: Enables internal channels, lattices, or organic shapes unachievable by subtractive methods.

Material Efficiency: Minimizes waste compared to CNC or EDM, critical for costly exotic materials.

Rapid Prototyping: Shortens design-to-test cycles for prototype machinists in aerospace or medical R&D.

Customization: Ideal for one-off or low-volume parts, like patient-specific implants or custom defense components.

Challenges

Surface Finish: AM parts often have rough surfaces (Ra 5–20 µm), requiring post-processing (e.g., machining, polishing, or coatings).

Speed: Slower for large parts compared to traditional methods; best for small to medium components.

Cost: High equipment and material costs, especially for metal AM, though cost-effective for complex or low-volume parts.

Material Limitations: Limited to specific metals, polymers, or ceramics compatible with AM systems.

Standards: Must meet MIL-STD-810, AS9100 (aerospace), or ISO 13485 (medical) requirements, necessitating rigorous testing (e.g., NDT, CMM).

Specific Relevance

Aerospace/Defense: AM produces lightweight, high-strength parts like waveguides or chassis, reducing weight by up to 50% compared to traditional methods, critical for fuel efficiency or payload capacity.

Medical: AM’s ability to create porous titanium structures enhances osseointegration in implants, while SLA provides high-resolution parts for surgical tools.

Prototyping: AM supports rapid iteration, complementing the work of prototype machinists by producing initial parts that EDM or Swiss machining refines.

Additive Manufacturing is a game-changer for precision industries, offering unmatched flexibility for complex designs and exotic materials. When paired with subtractive processes (e.g., EDM, Swiss machining) or coatings (e.g., plasma spray), it delivers high-performance components for aerospace, defense, and medical applications, streamlining prototyping and production.

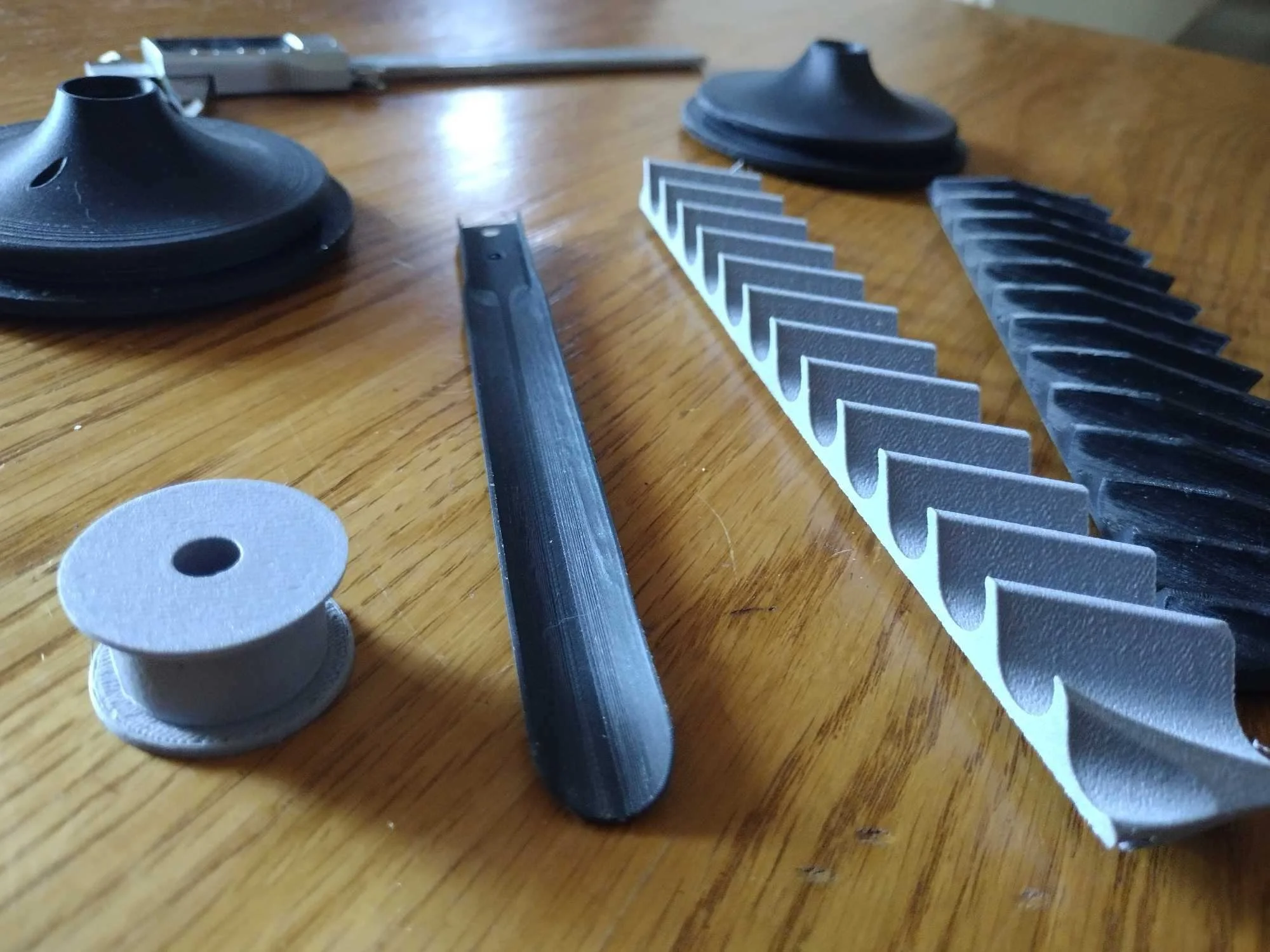

NFC chipped company logo discs

3D Print for prototyping