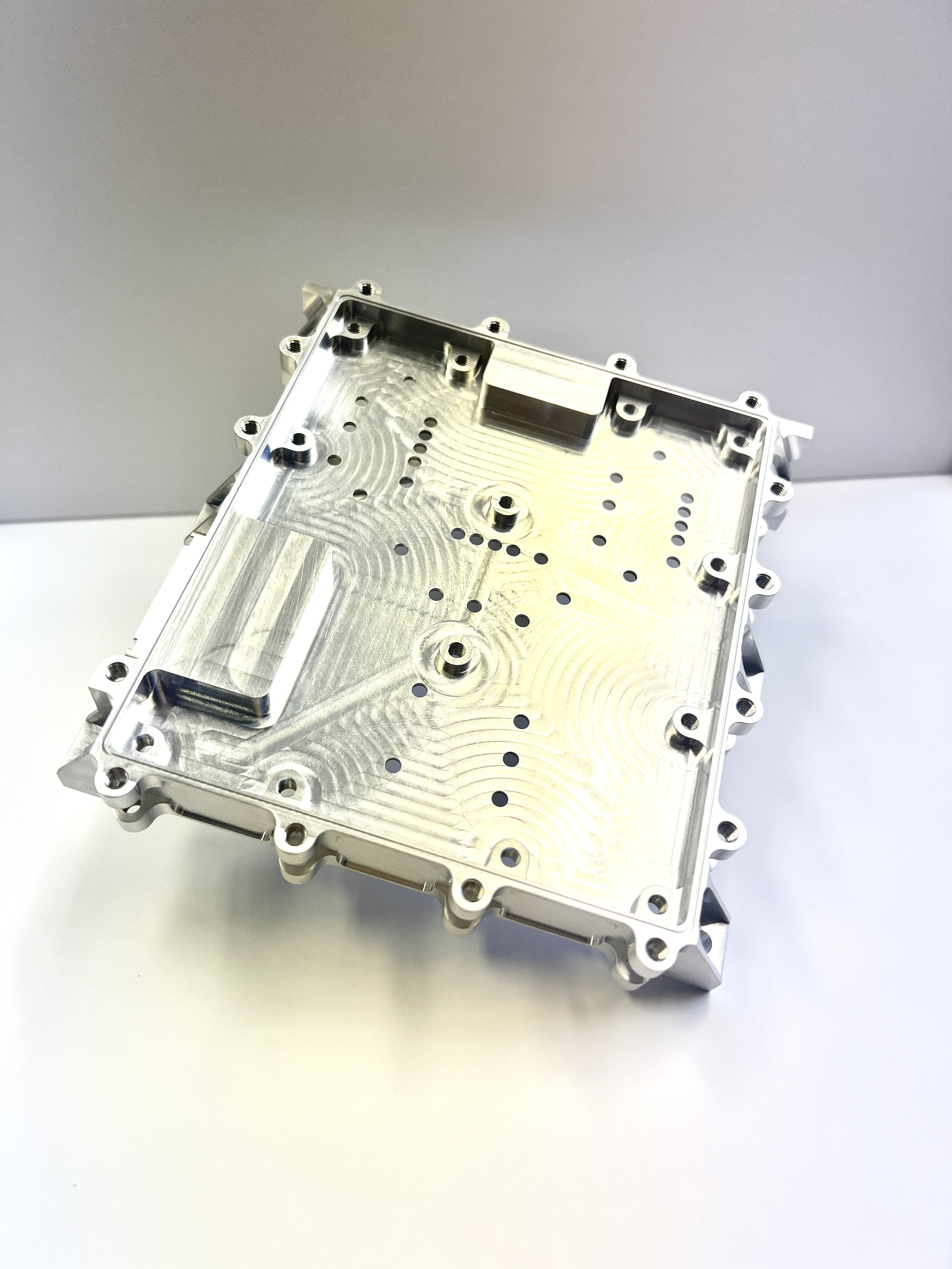

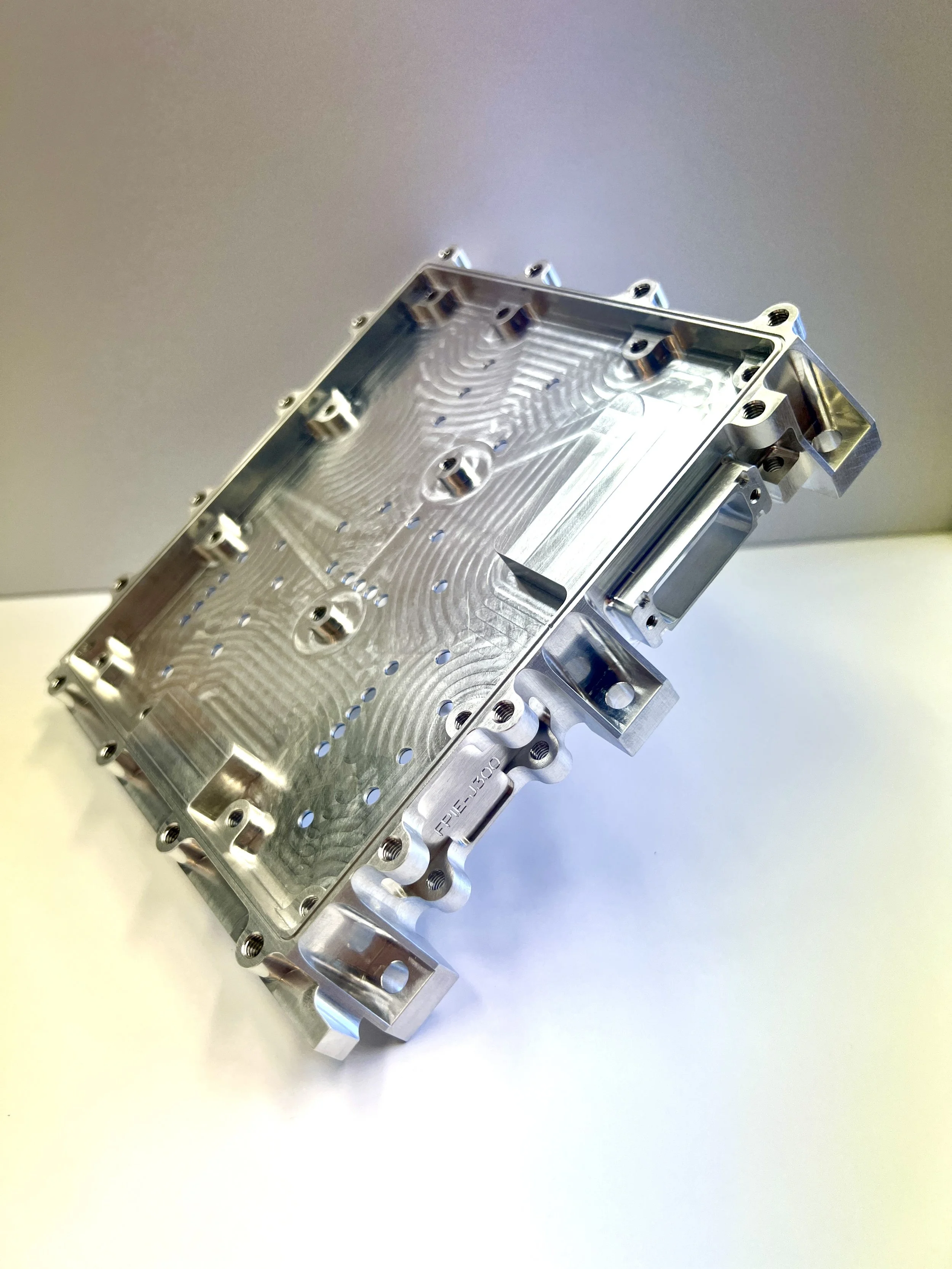

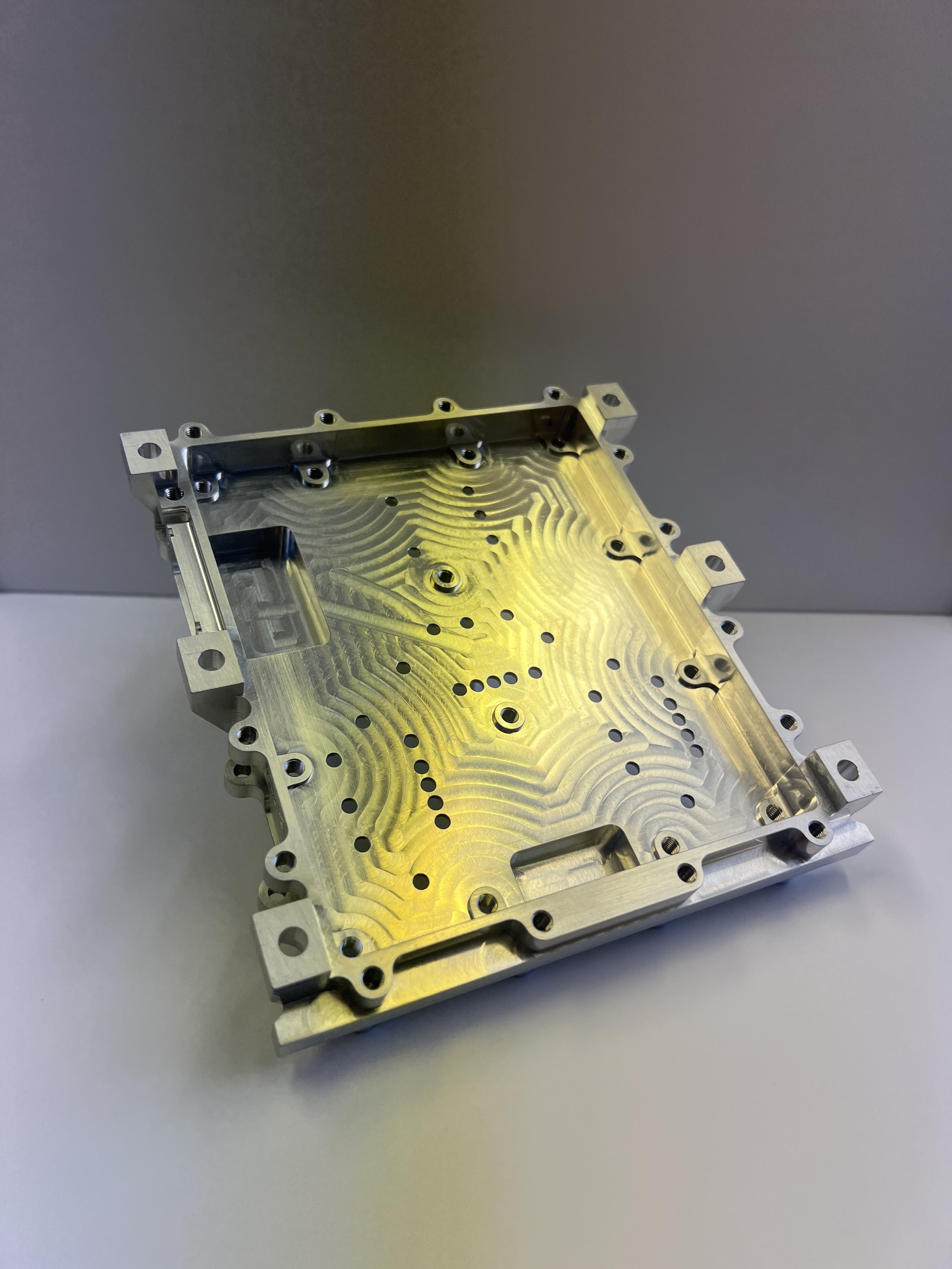

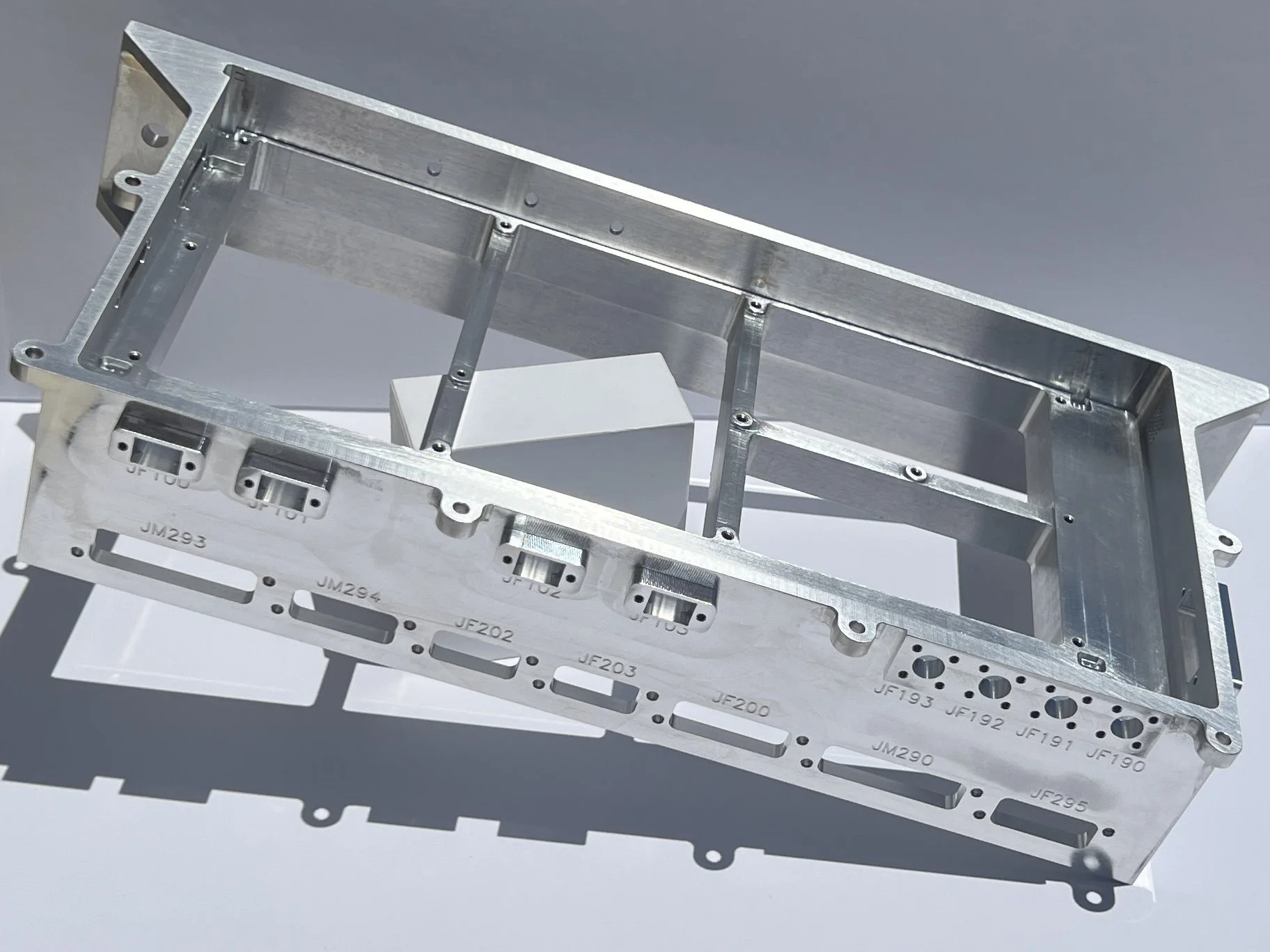

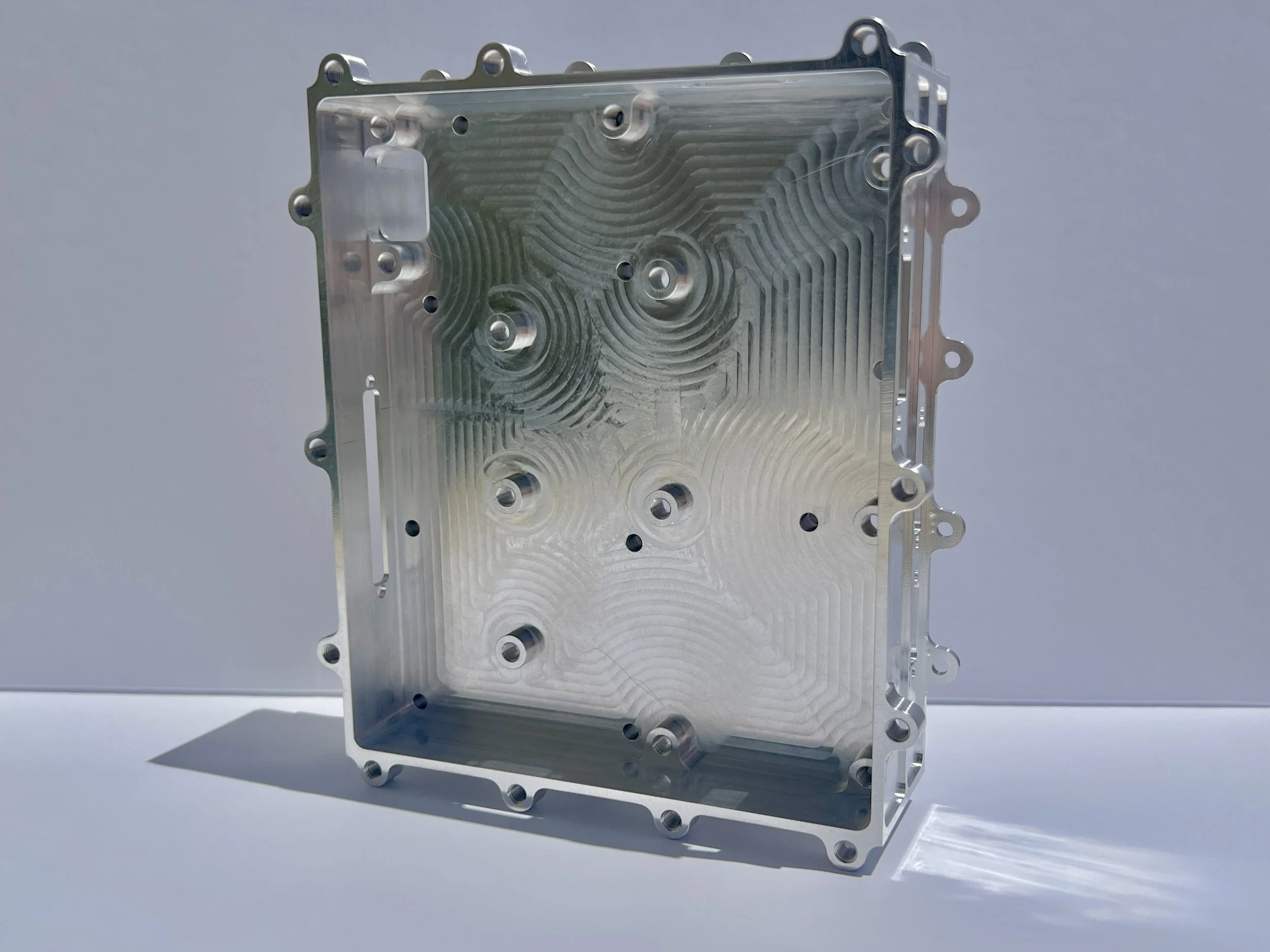

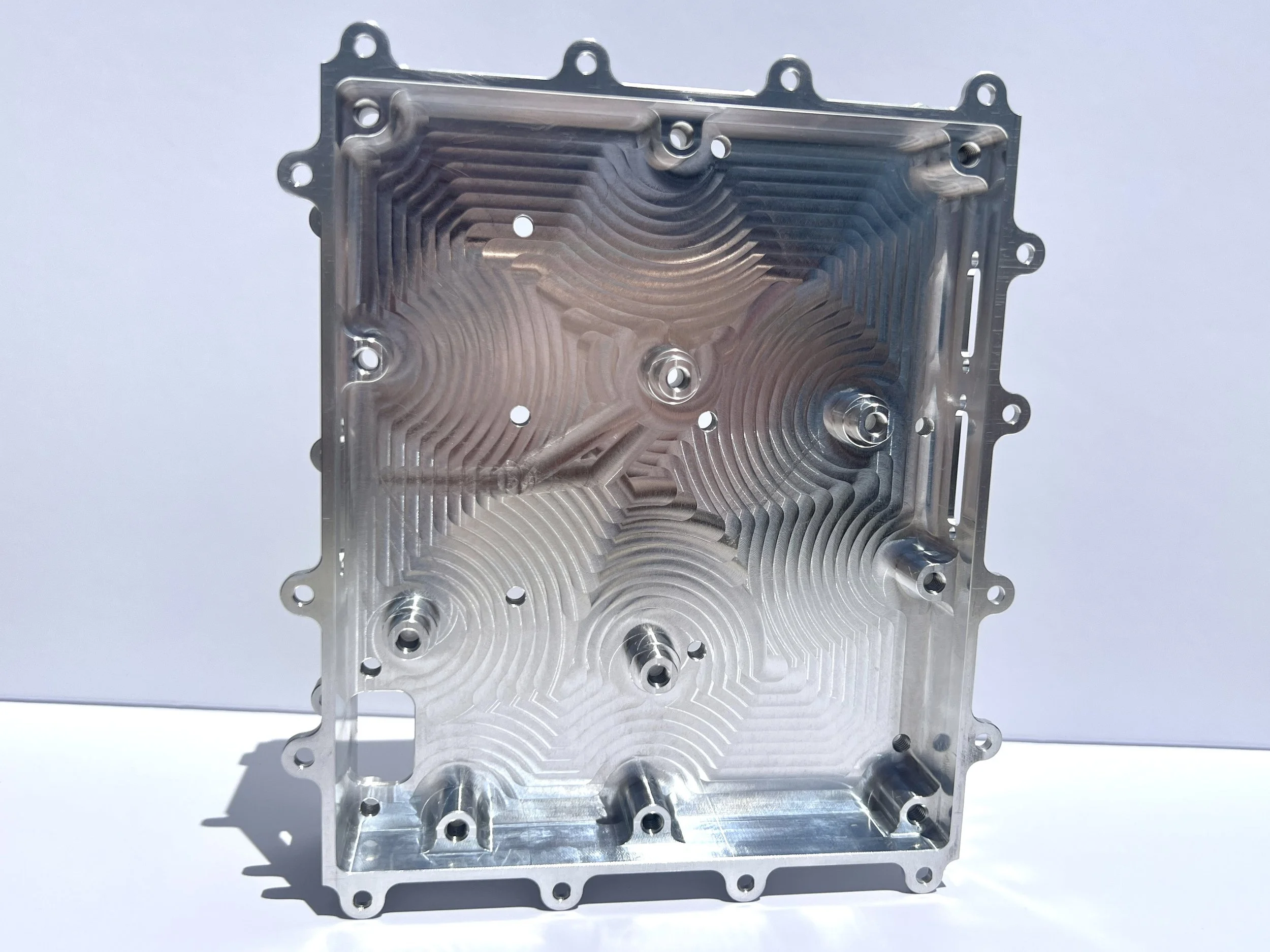

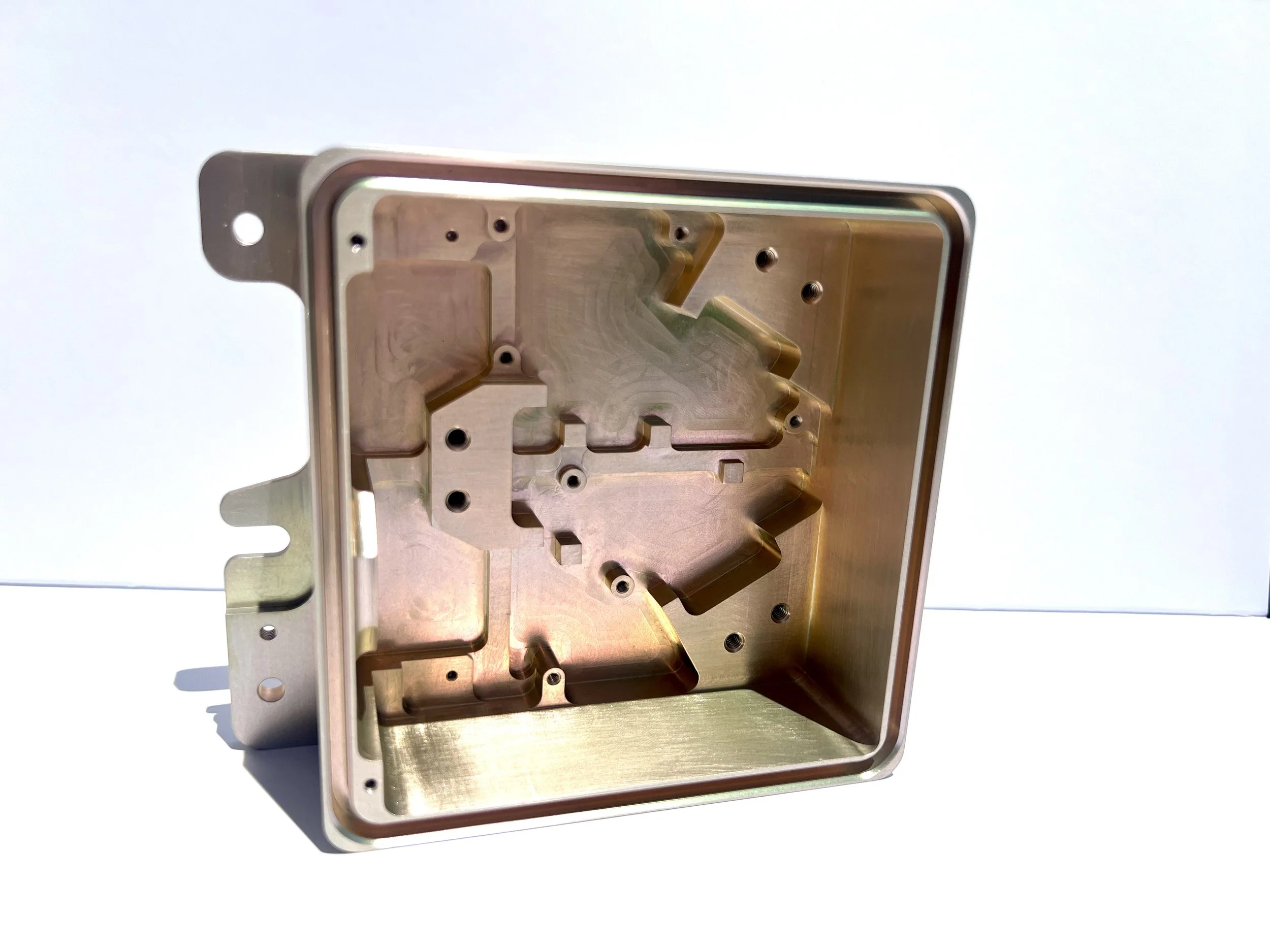

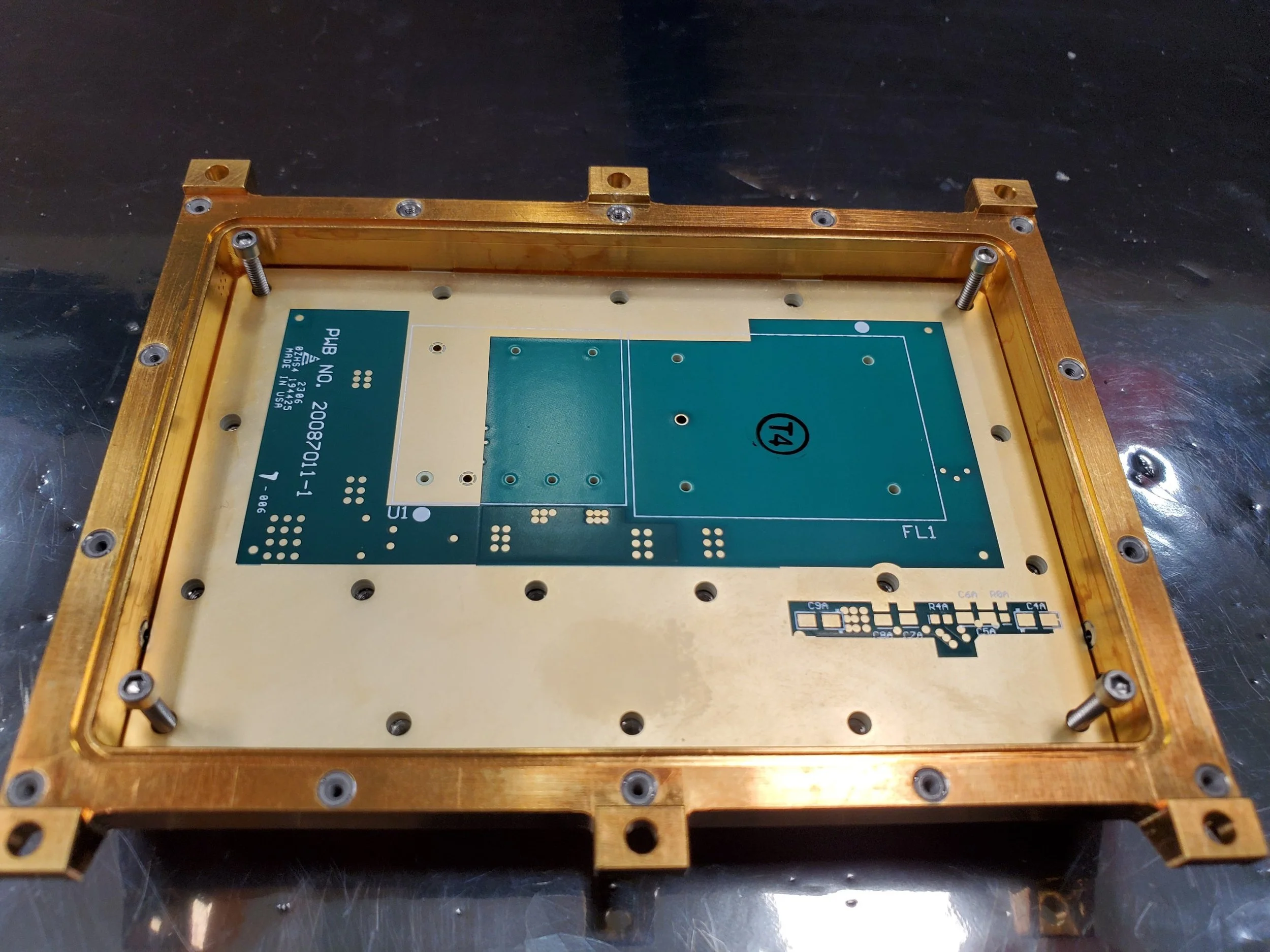

Electronic Chassis Fabrication

Aerospace and defense electronic chassis fabrication involves designing and manufacturing ruggedized enclosures or frames to house sensitive electronic components, such as PCBs, wiring harnesses, and computing modules, in mission-critical systems. These chassis provide structural support, thermal dissipation, electromagnetic interference (EMI) shielding, and protection against extreme conditions like vibration, shock, temperature fluctuations, and environmental hazards, ensuring reliability in air, sea, and ground applications. Common standards include AS9100 for quality, MIL-STD-810 for environmental testing, and MIL-STD-461 for EMI compliance, with ITAR regulations governing export-sensitive production.

Key Processes and Materials

Materials: Primarily lightweight aluminum alloys (e.g., brazed per MIL-B-7883) for strength-to-weight ratio and conductivity, with growing use of composites or hybrids for enhanced vibration damping and thermal management.

Fabrication Techniques: Machining, forming, extrusion, CNC precision cutting, and welding to achieve tight tolerances; often integrated with assembly for box builds or subassemblies.

Configurations: ATR (Air Transport Rack) short enclosures for avionics, 3U/6U VPX/VME/Compact PCI racks for modular computing, and custom rack-mountable designs compliant with SOSA (Sensor Open Systems Architecture).

This fabrication supports high-reliability electronics manufacturing services (EMS) for prototyping, low-volume production, and sustainment, reducing non-recurring engineering costs while enabling rapid deployment in defense programs.

Electronic Flight Chassis