Precision Waveguide Machining

Precision waveguide machining is the specialized process of fabricating waveguides—hollow metallic structures that guide electromagnetic waves, typically for microwave and RF applications—with high accuracy and tight tolerances. Used extensively in aerospace, defense, telecommunications, and medical industries, waveguides require precise dimensions to ensure efficient signal transmission with minimal loss or distortion.

Key Aspects

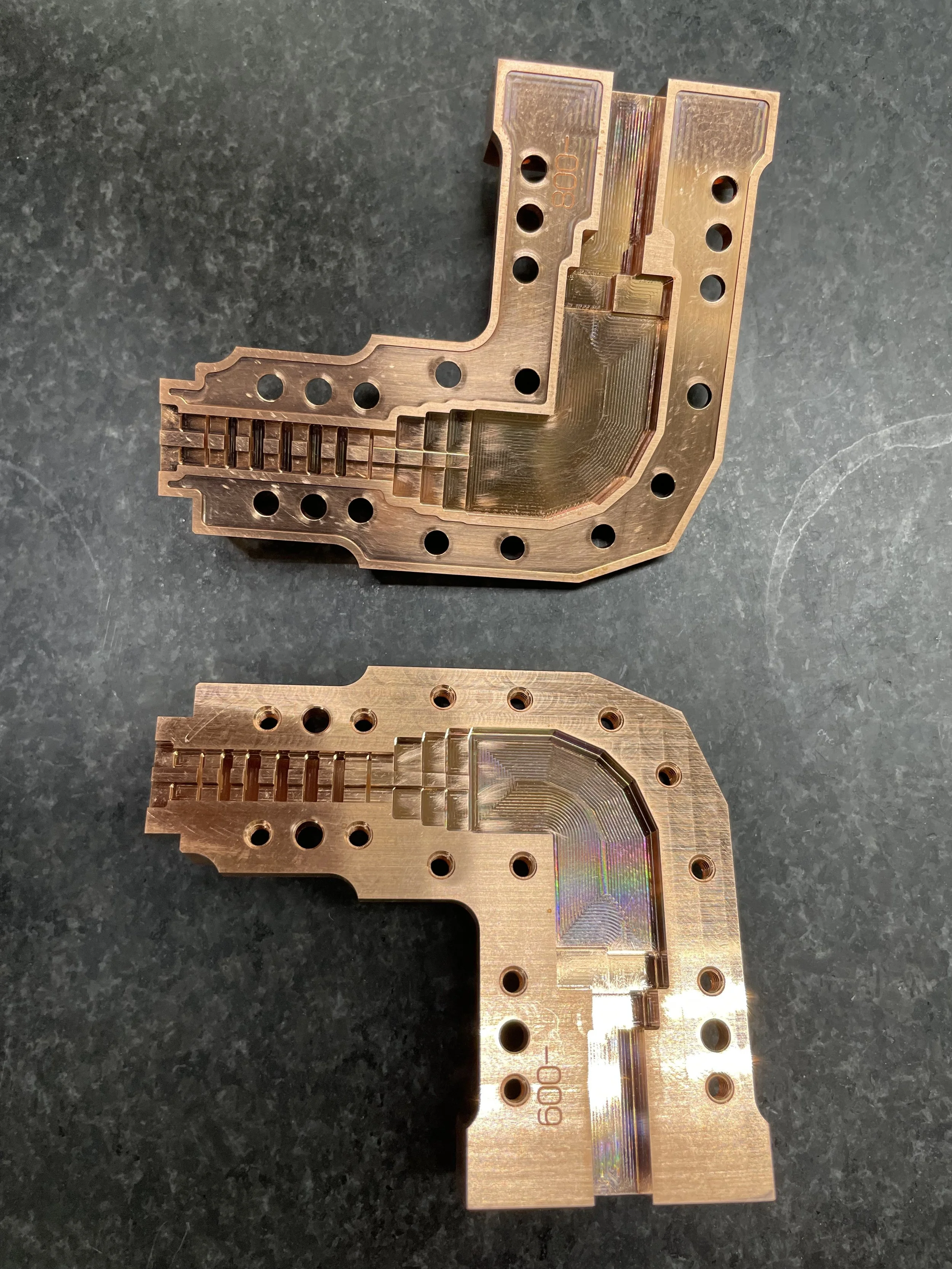

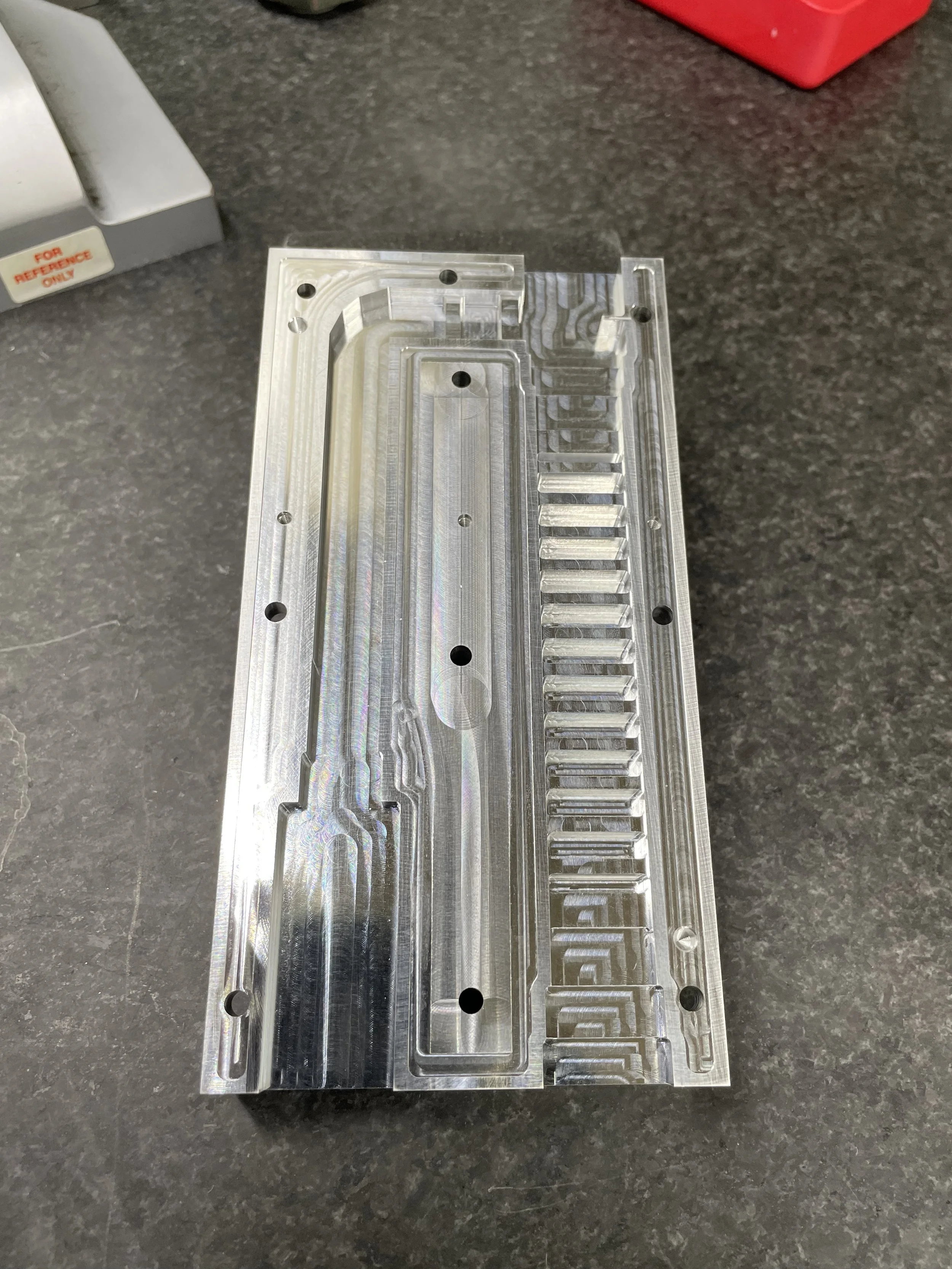

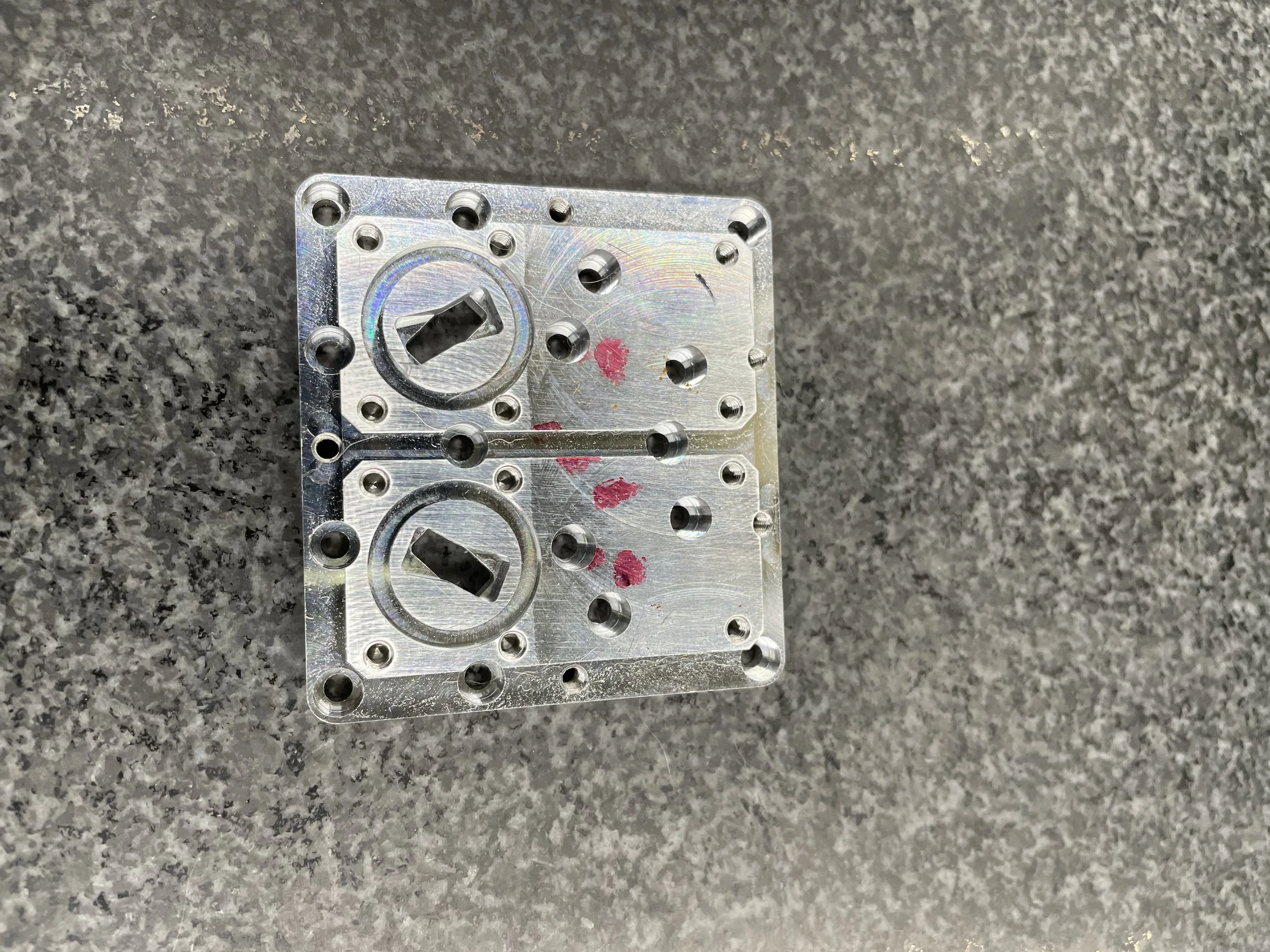

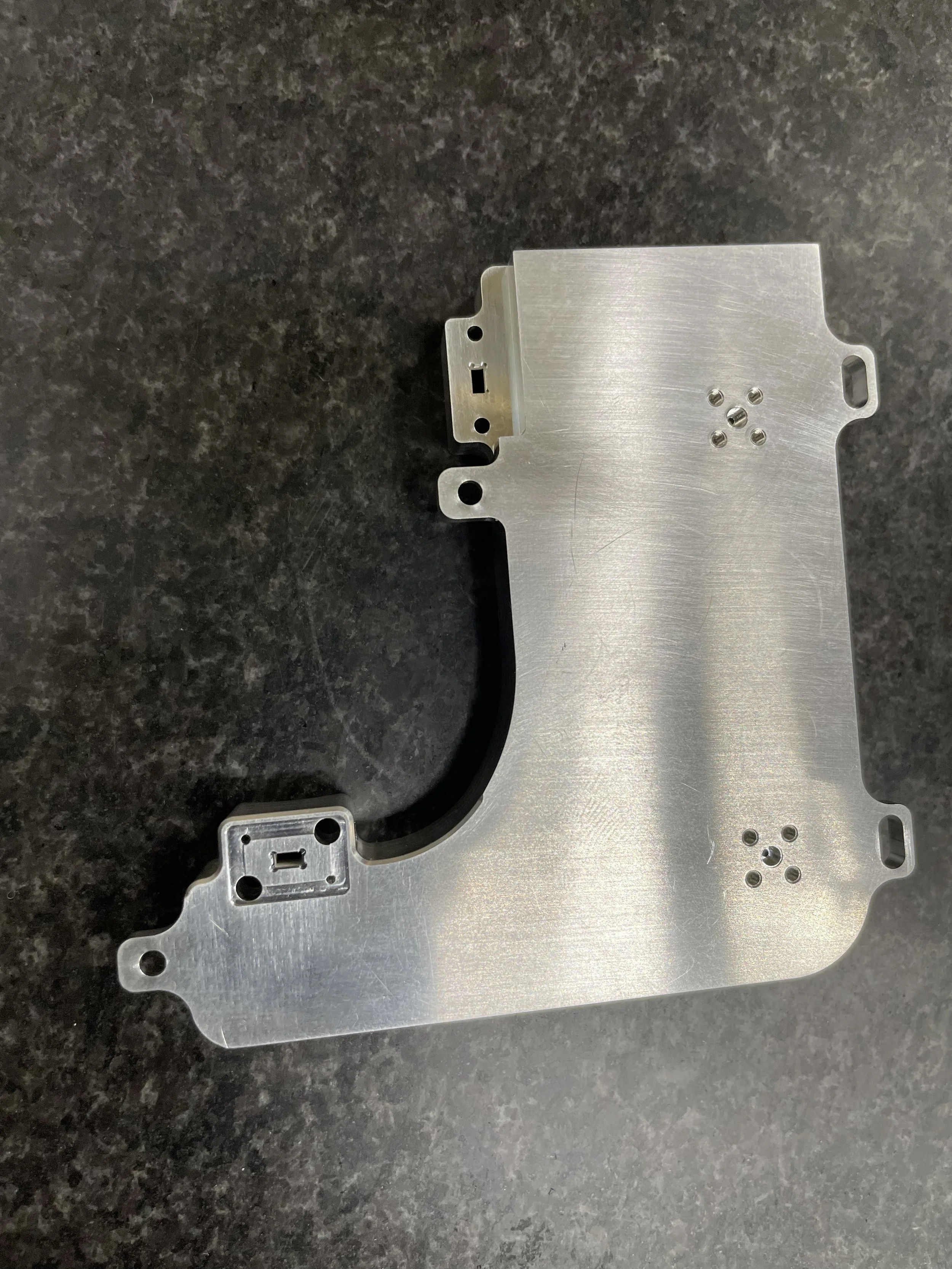

Materials: Typically - aluminum, copper, brass, or silver-plated metals for high conductivity and low signal loss. Exotic materials like Invar or titanium may be used for specific thermal or strength requirements.

Processes:

CNC Machining: High-precision CNC milling or turning to achieve tolerances as tight as ±0.0005 inches for critical dimensions.

Electroforming: Depositing metal onto a mandrel to create complex waveguide shapes with smooth surfaces.

EDM (Electrical Discharge Machining): Used for intricate geometries or hard materials where traditional machining is challenging.

Brazing/Welding: Joining waveguide sections while maintaining structural integrity and electrical continuity.

Surface Finishing: Polishing or plating (e.g., silver or gold) to reduce signal attenuation and improve conductivity.

Applications:

Aerospace/Defense: Radar systems, satellite communications, and avionics (e.g., slotted waveguide antennas).

Telecommunications: 5G/6G infrastructure, microwave links.

Medical: MRI systems and RF-based diagnostic equipment.

Standards: Must meet stringent specifications like MIL-STD-810 for environmental durability or MIL-W-85 for waveguide performance.

Challenges: Achieving precise internal dimensions, smooth surfaces to minimize signal loss, and maintaining structural integrity under thermal or mechanical stress.

Why Precision Matters

Waveguides operate at high frequencies (e.g., 1-100 GHz), where even minor dimensional inaccuracies can cause signal degradation, impedance mismatches, or increased losses. Advanced techniques like 5-axis CNC machining and rigorous quality control (e.g., CMM inspection) ensure performance in critical systems like fighter jet radar or satellite transponders.

This process often integrates with 3D printing for prototyping or hybrid manufacturing, combining additive and subtractive methods to achieve complex designs with reduced lead times.